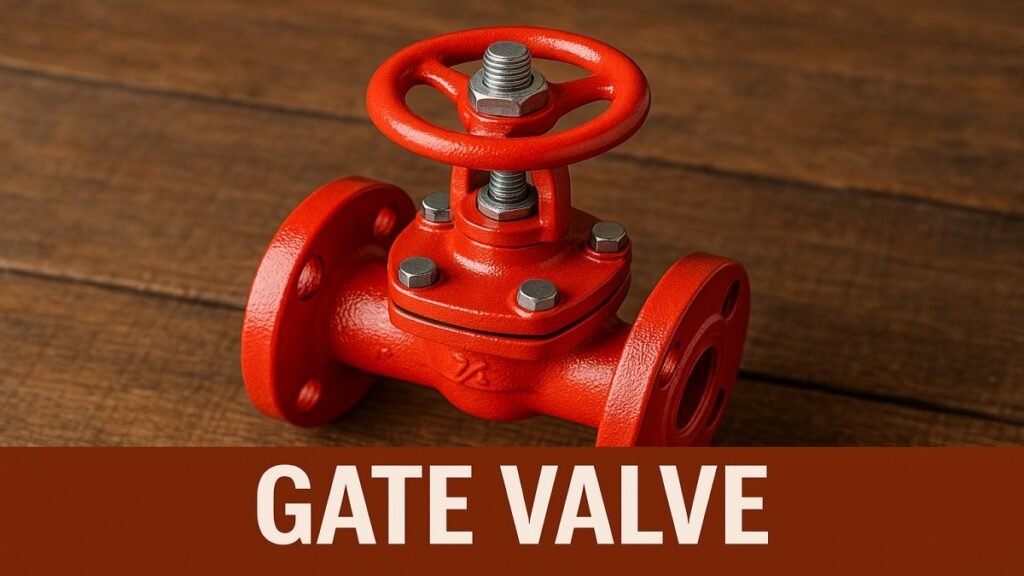

Introduction to Gate Valves

What Is a Gate Valve?

A gate valve is a mechanical device used to start or stop the flow of liquid through a pipe. It operates by raising or lowering a gate (also known as a wedge) inside the valve body. When the gate is fully raised, the flow is unrestricted. When lowered, the flow is completely stopped.

Purpose and Applications

Gate valves are primarily used in systems where a straight-line flow of fluid and minimum restriction is needed. Think of them as the old-school on/off switches for fluid systems — no halfway, just flow or no flow.

History and Evolution

The gate valve has been around for over a century, with improvements in design, materials, and automation. Initially used in waterworks and railroads, it has now found a home in virtually every fluid-based industry.

Types of Gate Valves

Based on Disc Design

Solid Wedge Gate Valve

A solid, single-piece wedge — strong and simple but not ideal for thermal expansion.

Flexible Wedge Gate Valve

Has a cut on the wedge to allow slight flexibility, reducing the risk of binding in fluctuating temperatures.

Split Wedge Gate Valve

Two separate discs allow better sealing in uneven seating surfaces.

Based on Stem Design

Rising Stem

The stem rises as the valve opens, giving a clear visual indication of valve status.

Non-rising Stem

Stem doesn’t move up; ideal for limited space applications.

Based on Material

Brass

Cost-effective and corrosion-resistant for household applications.

Stainless Steel

Durable and ideal for harsh industrial environments.

Cast Iron

Affordable and suitable for water and steam systems.

Key Components of a Gate Valve

- Valve Body: The main casing.

- Bonnet: Covers the stem and packing.

- Stem: Connects the gate to the actuator or handwheel.

- Gate/Wedge: The component that blocks or allows flow.

- Seat Rings: Provide the sealing surfaces.

- Actuator/Handwheel: Manual or automatic control mechanism.

How Gate Valves Work

Open-Close Mechanism

The gate is lowered into the flow path to stop flow and lifted out to allow it. It’s not designed for flow regulation — just full stop or full go.

Sealing and Flow Control

Sealing is achieved when the gate presses tightly against the seats. This minimizes leaks.

Differences From Globe and Ball Valves

Unlike ball or globe valves, gate valves don’t handle pressure drops or flow regulation well.

Advantages and Disadvantages

Pros:

- Low-pressure drop

- Bidirectional

- Tight sealing

Cons:

- Slow operation

- Not for throttling

- Prone to wear if partially open

Where Are Gate Valves Used?

- Water supply and sewage systems

- Oil and gas pipelines

- Power generation

- Chemical manufacturing

Gate Valve Installation Tips

- Always install in the correct direction.

- Fully open or fully close before use.

- Ensure valve is compatible with the pipe material.

Maintenance and Troubleshooting

- Check for corrosion or debris.

- Lubricate moving parts regularly.

- If valve sticks, do not force it — investigate first.

Gate Valve Standards and Certifications

- API 600/602

- ASME B16.34

- ISO 10434

These ensure the valve can handle pressure and temperature ratings for critical applications.

Manual vs. Automated Gate Valves

- Manual: Cheaper, used in non-critical systems.

- Automated: Used in systems needing remote or rapid operation (e.g., emergency shutdown systems).

Innovations in Gate Valve Design

Modern gate valves feature:

- Sensors and IoT integration

- Improved alloys for longer life

- Zero-leakage technology

Environmental Considerations

- Use of lead-free materials

- Improved sealing to prevent leaks and waste

- Eco-friendly coatings

Choosing the Right Gate Valve

Consider:

- Fluid type

- Temperature and pressure

- Space constraints

- Budget

Buying Tips and Price Range

- Basic brass valves: $20–$100

- Industrial stainless steel: $200–$1000+

- Trusted brands: Velan, KITZ, Crane, Emerson

Conclusion

Gate valves may look like just another plumbing part, but they’re critical to controlling flow in nearly every fluid-based system. Whether you’re designing an industrial pipeline or just fixing a home water line, picking the right type of gate valve matters. Make sure you understand the flow, pressure, and system requirements and always install with care!

FAQs

Q1: Can a gate valve be used to throttle flow?

No. It’s designed for full open or full close, not partial flow control.

Q2: What’s better — ball valve or gate valve?

Depends on the use. Ball valves are faster; gate valves are better for isolation.

Q3: How long do gate valves last?

With proper maintenance, 10–20 years or more in non-corrosive systems.

Q4: Are gate valves suitable for high-pressure systems?

Yes, when properly rated (look for API or ASME certification).

Q5: How do I know if my gate valve is failing?

Stiff operation, leaks, or unusual noise during operation are key signs.