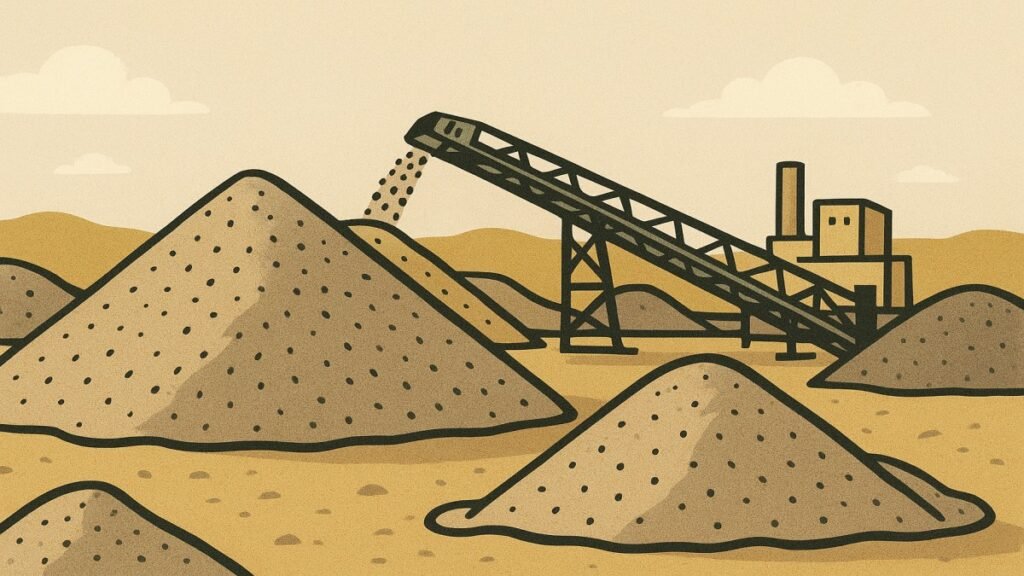

Gravel pits may look like simple excavated holes in the ground, but they play an essential role in construction, industry, and local economies. Found in many regions around the world, these open-pit mines are the primary source of gravel a fundamental raw material used for building roads, drainage systems, concrete structures, landscaping, and countless other applications. Understanding how gravel pits form, how they operate, and how they affect the environment helps us appreciate their importance and the need for responsible management.

What Are Gravel Pits?

A gravel pit is an open excavation where natural gravel is extracted from the earth. Gravel itself is a mixture of small rock fragments produced through natural geological processes like weathering, erosion, and glacial movement. These pits are typically located near river valleys, glacial deposits, and sediment-rich areas where gravel is abundant and easy to access.

Unlike quarries, which usually extract solid rock, gravel pits focus on loose aggregates. This makes extraction easier and less energy-intensive, but it also poses unique environmental and operational challenges.

How Gravel Pits Form Naturally

Gravel deposits form over tens of thousands of years due to:

1. Glacial Activity

In colder regions, glaciers grind rocks into smaller fragments. When glaciers melt, these sediments are deposited in layers known as outwash plains or kame terraces, creating ideal gravel sources.

2. River and Stream Erosion

Flowing water breaks down rocks and transports sediments. Over time, these deposits accumulate along riverbanks, riverbeds, and floodplains.

3. Weathering of Parent Rock

Continuous exposure to wind, rain, temperature fluctuations, and chemical processes breaks large rocks into smaller pieces that gather in low-lying areas.

These natural processes produce gravel beds that are eventually excavated through mining operations.

Types of Gravel Extracted from Pits

Different gravel types serve different purposes:

- Pea Gravel – small, smooth, commonly used in landscaping.

- Crushed Gravel – angular pieces ideal for driveways and construction.

- River Run Gravel – naturally rounded stones found in river deposits.

- Pit Run Gravel – large, unprocessed mix of sand, clay, and small stones used as base material.

Each variety influences how gravel pits operate and what machinery is needed.

How Gravel Pits Operate

Gravel pit operations involve several steps:

1. Site Assessment

Before excavation begins, geological surveys determine the depth and quality of gravel. Environmental impact assessments are often required.

2. Clearing and Stripping

Vegetation and topsoil are removed and stored for later site restoration.

3. Extraction

Machinery such as:

- excavators

- bulldozers

- draglines

- front loaders

…is used to scoop out raw gravel.

4. Sorting and Washing

Gravel is screened into different sizes, and in some pits, water is used to wash away fine sediments.

5. Transportation

Processed gravel is loaded into trucks and delivered to construction sites or processing facilities.

Major Uses of Gravel

Gravel is one of the most versatile materials in the construction industry. Key uses include:

1. Road Construction

Gravel forms the base layer beneath asphalt, providing stability and drainage.

2. Concrete Production

Mixed with sand, cement, and water, gravel adds strength and bulk to concrete.

3. Drainage Systems

Because of its permeability, gravel is used in French drains, septic systems, and retaining wall backfill.

4. Landscaping and Aesthetic Uses

Decorative gravel is used for pathways, garden beds, water features, and outdoor designs.

5. Erosion Control

Gravel helps prevent soil erosion along slopes, riverbanks, and construction sites.

Conclusion

Gravel pits might not immediately appear significant, but they’re vital to modern society. They supply the raw materials needed for transportation systems, buildings, water management, and countless everyday structures. However, like all resource extraction, gravel mining requires responsible management to protect the environment. When properly operated and rehabilitated, gravel pits can transform into valuable community assets—from recreational lakes to wildlife habitats. Understanding their importance helps us appreciate both their economic benefits and the need for sustainable mining practices.

FAQs

1. How long does a gravel pit stay active?

It depends on the size of the deposit and demand, but many gravel pits operate for 10–50 years.

2. Do gravel pits harm groundwater?

They can if not managed properly. Good water management prevents contamination and protects aquifers.

3. What is the difference between a quarry and a gravel pit?

A quarry extracts solid rock, while a gravel pit removes loose aggregates like sand and gravel.

4. Can gravel pits be turned into lakes?

Yes. Many abandoned pits naturally fill with groundwater and become recreational or wildlife lakes.

5. Are gravel pits noisy?

Mining equipment generates noise, but modern pits use noise barriers and scheduling to reduce impact.