Introduction

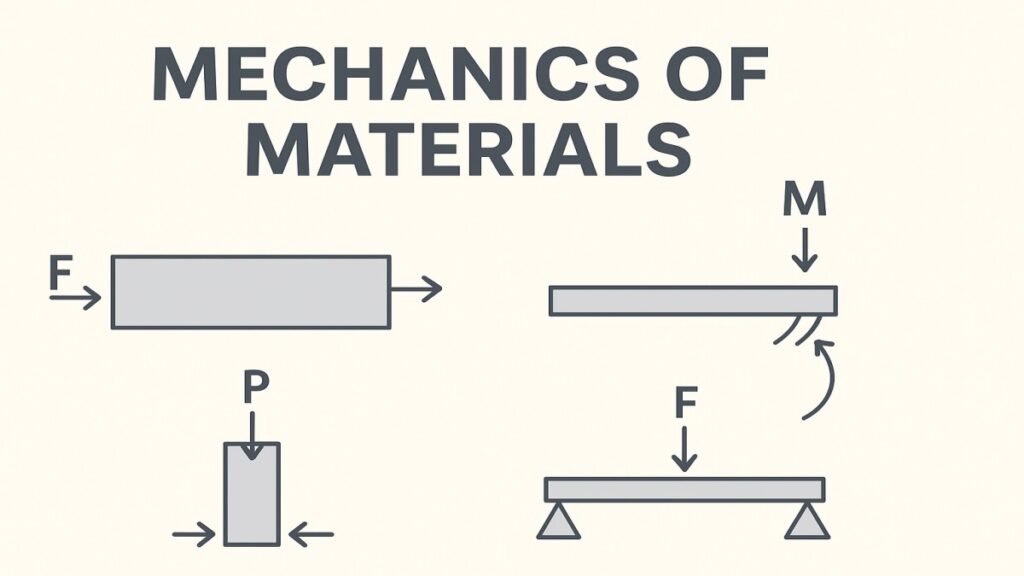

Every building, bridge, car, and airplane we see stands tall because of one critical field Mechanics of Materials. It’s the science that ensures materials can bear the forces and stresses we put on them. Without it, our modern infrastructure would crumble—literally.

What is Mechanics of Materials?

Mechanics of Materials, also known as Strength of Materials, is a branch of engineering that studies how different materials respond to external forces such as tension, compression, bending, and torsion. It helps engineers determine whether a structure is strong enough to perform safely and efficiently.

The Importance of Mechanics of Materials

Imagine designing a bridge without knowing how much weight its beams can handle. The result could be catastrophic. This field helps predict failure points, optimize material use, and enhance safety in design. It’s the foundation of civil, mechanical, and aerospace engineering.

Basic Concepts in Mechanics of Materials

Stress

Stress is the internal resistance offered by a material when an external force is applied. It is measured as force per unit area (usually in Pascals).

Strain

Strain measures how much a material deforms under stress. It’s the ratio of change in length to the original length—showing how “stretchy” or “stiff” a material is.

Elasticity

Elasticity is a material’s ability to return to its original shape after the force is removed. Think of it as the “memory” of the material—like a rubber band snapping back.

Types of Loads on Materials

Tensile Load

A force that pulls apart a material, stretching it—like when you pull on a rope.

Compressive Load

A force that pushes together a material—like the pressure on the columns of a building.

Shear Load

A force that acts parallel to a surface, causing layers to slide against each other—similar to the action of scissors cutting paper.

Stress-Strain Relationship

Hooke’s Law

This fundamental law states that stress is directly proportional to strain within the elastic limit of a material. Mathematically,

σ = E × ε,

where E is the modulus of elasticity.

Elastic and Plastic Deformation

- Elastic deformation: Temporary change; the material returns to its original shape.

- Plastic deformation: Permanent change after the stress exceeds the elastic limit.

Properties of Materials

Strength

The maximum stress a material can withstand without breaking.

Ductility

The ability of a material to deform before breaking—like how metals can be drawn into wires.

Toughness

A measure of how much energy a material can absorb before fracturing.

Hardness

Resistance to surface indentation or wear—important for tools and machinery.

Types of Stresses

Normal Stress

Occurs perpendicular to the surface—common in tension or compression.

Shear Stress

Acts parallel to the surface, causing one layer to slide over another.

Bearing Stress

Develops when one body presses against another—such as a bolt inside a hole.

Moment of Inertia and Its Importance

The moment of inertia measures how a cross-sectional shape resists bending. The larger the value, the stronger and stiffer the beam. This is why I-beams are commonly used—they have high strength with minimal material.

Torsion and Its Effects

Torsion refers to twisting caused by an applied torque. Shafts and axles experience torsional stress daily in vehicles and machinery. The ability to resist twisting determines performance and safety.

Bending of Beams

Bending Stress

When beams bend, the top surface stretches (tension), and the bottom compresses. The neutral axis lies in between, experiencing no stress.

Neutral Axis

The imaginary line in a beam where the material experiences zero stress during bending.

Conclusion

The mechanics of materials is more than just equations and theories—it’s the art and science of ensuring safety, durability, and performance in everything we build. From towering skyscrapers to the smallest machine parts, understanding how materials behave under load is what keeps our modern world standing strong.

FAQs

1. What is the main purpose of studying mechanics of materials?

To analyze how materials respond to different forces and ensure structural safety and efficiency.

2. Is mechanics of materials difficult to learn?

It can be challenging, but with practice and understanding of physics basics, it becomes intuitive.

3. What careers use mechanics of materials?

Civil, mechanical, aerospace, and materials engineers all rely on this field.

4. What is the difference between stress and strain?

Stress is the internal force per unit area, while strain is the resulting deformation.

5. How is this field evolving with technology?

Through simulation tools, smart materials, and AI-driven structural analysis improving accuracy and safety.